|

DONGGUAN CUTCNC EQUPMENT CO.,LTD

|

laser die making machine

| Payment Terms: | T/T |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

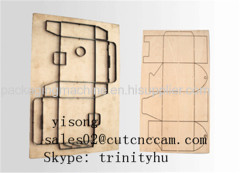

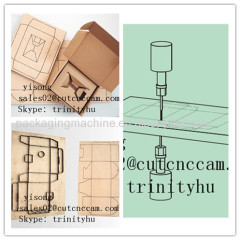

laser die making machine cut wood die board make die board kerf cutting by milling bit instead of laser

laser die making machine

1. We own the latest multi-axis CNC control technology fromGermany, R&D the control system with proprietary intellectual property rights, has powerful function and good scalability.

2. The automatic CAD / CAM programming control software, Automatically optimize layout and cutting path, automatically processing bad intersection, breakpoint, Singular element, automatically setting eliminate tangent, automatic setting elimination for bad drawing join and tangency, identification variety CAD files.

3. Users can also build their special cutting technology database, Directly selecting appropriate processing program from the the database, very simple and fast.

4.Users can make process of nesting, Path optimization, patch systematic arrangement, adjusting the cutting direction, resetting cutting starting point, simulation cutting and other various processing details and options easily.

5.The X,Y,Z axis is equiped with top brand servo motor and drive, good performance, fast response, maintenance-free.

6. Equiped with top brand high-precision servo, precision linear guide, bearing, guaranteeing operation precise.

7. Equiped the dust collect system, Protecting the machine transmission parts and industrial environment from dust pollution.

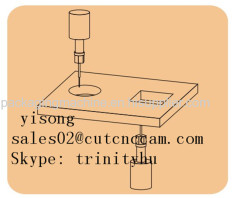

8.Milling bit determine top and button kerf exactly the same, both curves and Arc line knife up and down all vertical, kerf interface closed well.

9.Low cost, only need normal kind of milling, no need other consumables.

10.Without any kinds of gas ,green environmental protection, no pollution, no radiation.

11. Low power consumption, no boot fee, no need waiting for boot, ready-to-use at any time

12.Suitable for processing variety of materials milling mould, plywood mould, bakelite plate, PVC board mould, acrylic sheet mould, aluminum sheet mould, counterplates , stripping plate mould.

13. Device structure stable and durable, easy maintenance, low maintenance costs.

Die board milling machine VS laser cutting machine:

Item | YiSong die board milling machine | High power(1200W)laser cutting machine | Low power (300W)laser cutting machine |

Milling Way | Milling and die line drawing | Laser cutting | Laser cutting |

Machine Precision | ±0.03mm~±0.05mm | >±0.03mm | >±0.05mm |

Repeatability | ±0.01mm | >±0.01mm | >±0.05mm |

Milling Speed | 3m/min. | <1m/min. | <0.6m/min. |

Kerf Gap Precision | upper and lower side is exactly the same | upper and lower side is nearly the same | upper and lower side is not the same |

Kerf Gap Width | 0.3-3mm adjustable | 0.3mm ~3mm adjustable | 0.3mm ~3mm adjustable |

Milling Thickness | 3mm ~25mm | 5mm ~25mm | 5mm ~25mm |

Quality | No matter curved line or straight line, the kerf gap of upper and lower side is exactly the same with vertical blade closure. | The kerf gap of upper and lower side is nearly the same with vertical blade closure. | Knife is not vertical. Blade closure is terrible. |

Consumables | Few consumable,only common routing bit. | Consumable cost is very high. Consumables includes: Gas, laser tube, lens, etc. | Consumable cost is very high. Consumables includes: Gas, laser tube, lens, etc. |

Update Functions | Engraving counterplates and stripping boards besides die board | Only for die board | Only for die board |

Stability | Diameter of router ensures the same kerf gap | Laser attenuates,unstable power cause different kerf gap | Laser attenuates,unstable power cause different kerf gap |

Environment Protection | No pollution | Serious pollution | Serious pollution |

Using Cost | Very low Using cost | Very high Using cost, nearly RMB90, 000/year. | Very high Using cost, nearly RMB30, 000/year. |

Boot Cost | No boot cost, immediate use | High boot cost, at least RMB300 each time. | No boot cost |

Operating Cost | Very low | Very high, at least RMB100,000 for machine and laser generator | Low |

Set-up Time | No set-up time, start at any time | 40 minutes | No set-up time, start at any time |

Working Materials | Aluminum board, wood board, bakelite plate, PVC board, acrylic board | Wood board, bakelite plate, PVC board, acrylic board | Wood board, bakelite plate, PVC board, acrylic board |

Health | No radiation, no dust. | Generate harmful radiation and dust | Generate harmful radiation and dust |

Safety | No lasers, no gas container | With lasers, gas container | With lasers, gas container |

Daily Maintenance | Simple | Structure complicated with long maintenance time | Structure complicated with long maintenance time |

Cooling Water | No need. | Pure water needed | Pure water needed |

Gas | No need. | Auxiliary inactive gas needed | Dry oil-free air needed |

Operation | Simple | Very Complicated | Complicated |

Occupy Dimensions | Small space, only machine area. | Large space,several individual spaces needed for laser generator, machine, gas disposal room, etc. | Large space,especially laser generator, machine occupy much space. |

Specification:

Type | DM50-0906 | DM50-1209 | DM50-1512 | DM50-1812 | DM50-2412 |

Working Area | 900mm×600mm | 1200mm×900mm | 1500mm×1200mm | 1800mm×1200mm | 2400mm×1200mm |

Milling Speed | 5 Meter per minute | 5 Meter per minute | 5 Meter per minute | 5 Meter per minute | 5 Meter per minute |

Machine Precision | ±0.03mm~±0.05mm | ±0.03mm~±0.05mm | ±0.03mm~±0.05mm | ±0.03mm~±0.05mm | ±0.03mm~±0.05mm |

Repeatability Precision | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm |

Data Format | PLT,EPS,BMP, DXF | PLT,EPS,BMP, DXF | PLT,EPS,BMP, DXF | PLT,EPS,BMP, DXF | PLT,EPS,BMP, DXF |

Power | 1.8kw/h | 2kw/h | 2.6kw/h | 3.0kw/h | 3.5kw/h |

Weight | 270kg | 300kg | 370kg | 410kg | 450kg |

Occupy Dimension | 1400mm×1400mm | 1700mm×1700mm | 2000mm×2000mm | 2300mm×2000mm | 2900mm×2000mm |

tel: 0086-13549354183

QQ: 2355895767

E-mail: sales02@cutcnccam.com

Skype: trinityhu

ICQ: 627-696-000

Yahoo: trinitylyzb@yahoo.com

MSN: trinityhu@hotmail.com

www.packagingmachiney.com